DESIGN AND MANUFACTURE MIXING/ AGITATORS AND PERSITALTIC HOSE PUMPS

SPECIALIZED MIXERS

PRESSURE OXIDATION

PRESSURE OXIDATION

PRESSURE OXIDATION

GAS DISPERSION

PRESSURE OXIDATION

PRESSURE OXIDATION

IRON REMOVAL

PRESSURE OXIDATION

CYANIDE REMOVAL

CYANIDE REMOVAL

PEDESTAL MOUNTED MIXERS

CYANIDE REMOVAL

PEDESTAL MOUNTED MIXERS

PEDESTAL MOUNTED MIXERS

PEDESTAL MOUNTED MIXERS

SOLVENT EXTRACTION

PEDESTAL MOUNTED MIXERS

PEDESTAL MOUNTED MIXERS

-

PRESSURE OXIDATION

Pressure Oxidation (POX). high-pressure oxidation (HiPOX) and ACTIVOX autoclave leaching are practical industry- standard technologies. These technologies are used to recover metals such as gold, copper, nickel, platinum and uranium. Once the metals are put into a solution, the valuable material can be recovered by processes such as electrowinning or chemical precipitation. Electrowinning is also known as electro-extraction, is the electrodeposition of metal from ores that have been put into a solution by a process called leaching. Chemical precipitation is the formation of a separable solid substance from a solution, either by converting the substance into an insoluble form or by changing the composition of the solvent to diminish the solubility of the substance in it. We have over the years supplied many agitators for autoclaves used in nickel, copper and platinum projects.

AFX has supplied agitators with the P4 impeller, with a proven track record in gas dispersion, to several projects in the platinum and base metal industry. After extensive research and development work, our dual impeller agitator, the P3 and P4 combination have been installed on numerous plants. The mechanical design of autoclave agitators requires extensive knowledge of the operating conditions. Furthermore, the understanding and ability to predict these extreme forces acting on the agitator drive are essential to a successful installation. The deign needs to accommodate these factors and protect ach component to eliminate any failures. At AFX, we have design programs incorporating this experience that ensures reliable, well- engineered agitators for high- pressure applications

-

GAS DISPERSION

Large volumes of gas are injected into the vessel-reactor through some type of dispersion unit, be it a sparge ring or pipe. Impellers for these applications must be carefully selected to prevent flooding of the impeller by the gas and to ensure effective dispersion, blending and solids suspension. The mechanical design of the systems is complex, with the agitator seeing large fluid forces and consequential shaft deflection.

AFX has many years of experience in the process and mechanical design of these agitators. The impeller of choice is the AFX high solidity P4 impeller, providing efficient operation at high gas induction rates. Gas dispersion applications include bio-oxidation processes (bacterial leaching) and dual impeller technology.

The lower impeller, known as the P4, is a downward-pumping, four blade, high-solidity hydrofoil impeller that has become the standard in bioleach reactors. It is designed to disperse high volumes of air, while also maintaining the solids in suspension and promoting heat transfer. Such impellers which typically have a solidity ratio of more than 90%, are characterised by their ability to operate at high gas volumes without flooding.

The upper impeller is the innovative aspect and is an upward-pumping triple- blade-medium solidity hydrofoil impeller. This impeller known as the P3 impeller was originally designed for high-viscosity applications but the diversity of the P3 impeller to operate through three-phase or gas- liquid- solids applications have also been realized.

The oxygen mass- transfer requirements of the BIOX® or bioleaching process with be satisfied at a lower input and aeration rate when compared to the previously established single- impeller system. The improved mass-transfer performance is achieved through surface air induction created by the top impeller which is enhanced by the gas hold-up form the specific mixing pattern created by the dual impeller configuration.

The air induced from the surface by the dual impeller installation results in the reduction of blower capacities and therefore results in blower power decreases. In addition to the improved process performance, the dual impeller system also demonstrates a reduction in a bending moment, torque and thrust which will extend the mechanical life of the agitator.

-

IRON REMOVAL

The iron is removed through a selective precipitation process of the ferric iron at the controlled pH level. After the initial metal leaching process, the iron is present as ferrous iron and an oxidation step is introduced to oxidise the ferrous iron to ferric iron for removal before precipitation. For this process, the oxidation is done through the introduction of large volumes of air in the presence of sulphur dioxide. For handling large volumes of air, the conventional ring sparges that are that are fitted below the impeller could result in flooding of the impeller and reduced efficiency.

AFX has developed the eight-point bull horn sparge to handle high volumes. On a typical ring sparge, the impeller would flood around 7% of the impeller pumping capacity. With this system, that number increased to over 20 %. The sparge is low maintenance and can handle high gas rates. In the application, air is being used as a carrier gas for the reaction. Gas is injected downwards towards the floor of the tank and as the gas begins to rise so the agitator draws it in and holds it down.

Unlike conventional ring sparges, the gas bubbles are not that fine when they are injected into the mixture. However, this is compensated for by the large gas hold up from the impeller and sparge combination. Therefore, if SO2 was not being added and rather SMBS, you will still get the desired efficiencies. As a result of these new developments, high gas volumes can now be efficiently handled in the iron removal processes for base metals.

-

CYANIDE REMOVAL

There are several processes available to destruct cyanide, with the most common process being the INCO method. This process route included the destruction of the cyanide in the presence of oxygen and sulphur dioxide. The oxygen is provided through large volumes of air or pure oxygen with sulphur dioxide gas or a solid reagent sodium called metabisulphite, to achieve maximum oxygen utilisation during the treatment process, specialised impellers are developed to yield oxygen utilisation from the compressed air ranging from 20% to 40 %. This depends on the percentage of solids in the slurry being treated. When pure oxygen gas is introduced, however this number could be as high as 80%.

-

PEDESTAL MOUNTED MIXERS

The design of large top entry agitators is often driven more by the requirement for the gearboxes to withstand high bending moments, as opposed to a requirement for high torque. As the gearboxes are always limited by torque and output shaft size selected accordingly, high bending moments often dictate the selection of large gearboxes. At AFX, we use independent bearing members for these applications, as this design allows the gearbox to be selected on the torque requirements only while the independent bearing member accommodates the high loads produced by the agitator. These pedestals or bearing members are carefully machined in a single setting to ensure accurate alignment of the intermediate shaft, gearbox and lower shaft. Special five- axis machines are used for this purpose.

-

SOLVENT EXTRACTION

When your pregnant liquor solution is contracted with an organic solvent, enough energy is required to prevent the phases from separating. This energy is entered into the system by a pump mixer, when too little energy is entered, the phases will separate.This is clearly evident in SX as the phases separate within the settler naturally and hence mixer-settlers (SX).

The mixers need to create dispersion and not an emulsion, as this would be the result of too much energy. The ideal dispersion is the minimum energy required to maintain a complete dispersion with in pockets of phase separation. Since the surface is the furthest away from the pump, this is the region where phase separation is most probable. This is convenient because the surface of a mixed box can be seen if the lids are removed.

At the minimum power per unit volume for complete dispersion, the droplets are the biggest stable droplets possible. This is ideal if top speed is kept down, to minimize fines and facilitate the separation in the settlers. The minimum power for phase separation has been determined experimentally. The minimum power per unit volume is a function of residence time and the height of the fluid. Tall skinning tanks need more power to resist phase separation than short, squat tanks. This is important to be considered during the design phase of the mix box. The best way to look at the design of the mix box is to determine the maximum possible hydraulic efficiency that can be achieved for the given head and flow and then determined the pump box volume.

Apart form the correct pump mixer design consideration being considered, we consider all available options when designing the mix box. We can assist with the best tank geometries as well as improve your mixer’s efficiency.

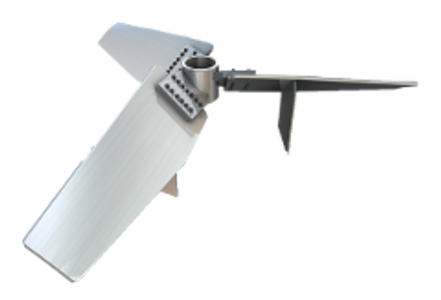

R6 Pump Impeller

This unique radial flow impeller is designed for pumper mixer applications. The impeller is designed to discharge the fluid radially outward to the vessel wall. This radial impeller provides a more informal radial flow pattern when compared to the radial impellers which do not have a disc. The advanced design ensures advanced flow, maximum dispersion and provides a specific and desired head generation. The curved blade pump turbines offer maximized head and flow while reducing air entrainment through low power consumption. Radial flow impellers are most commonly used in liquid-liquid dispersion applications.

F3 Turbine Mixer

The impeller used for the Turbine Mixer or Auxiliary Mixer is the AFX F3 hydrofoil impeller. The F3 are designed to deliver high pumping velocity at low power, versatility and suitable for high mixing efficiency in high and low viscosities, increasing scouring velocity and low shear rate- making it the ideal mixing impeller. The three – ear hub is keyed to the agitator shaft with the blades bolting onto it, together with the shaft in a single element. The adjustment allows for movement for the impeller after installation, to avoid phase separation. The F3 impeller is manufactured from 316 Stainless Steal.

Copyright © 2020 AFX Mixing & Pumping Technology Inc. - All Rights Reserved.

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies.